Engineered to handle your toughest food waste

Vogelsang's waste reduction equipment and pumps are perfect for food waste applications.

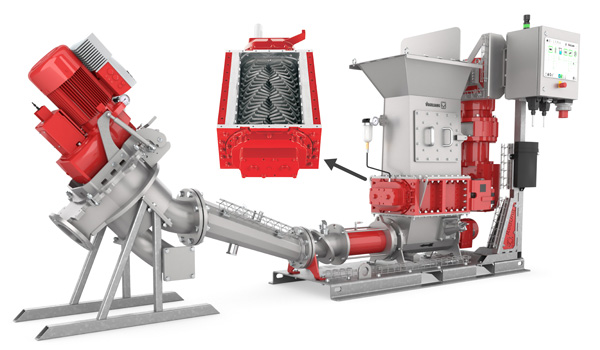

REDUNIT® System Solutions:

Reducing Hard solids, abrasives, pits, peels & packaging

What can RedUnit® offer?

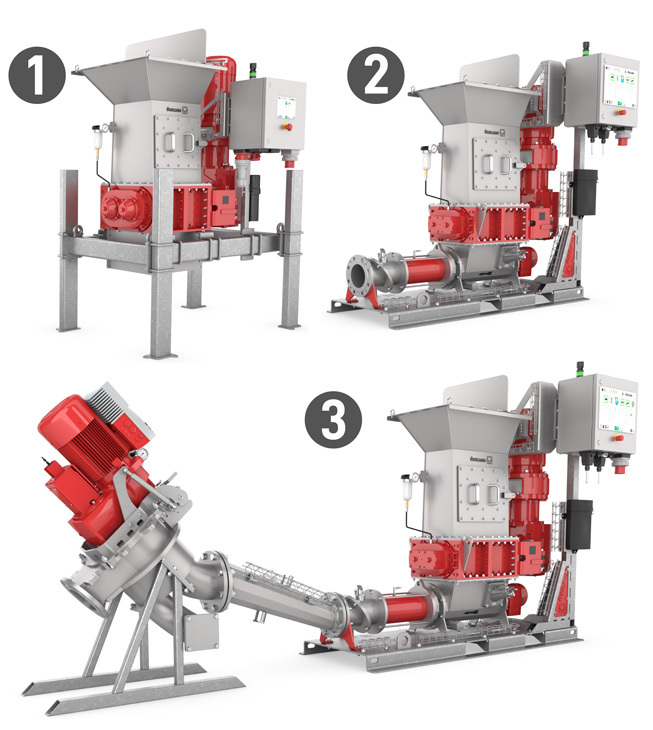

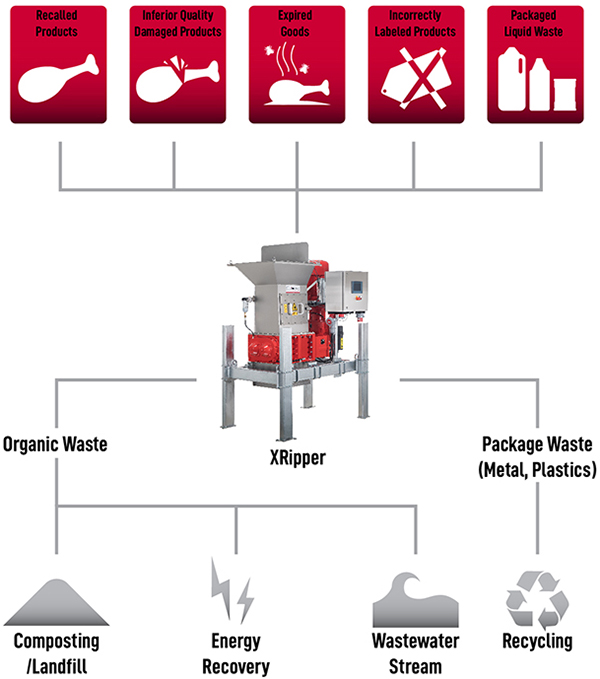

The Vogelsang RedUnit® line of products is a customizable platform of solids handling technology designed for reducing food scraps and other processing/manufacturing waste, including packaged food, into the necessary particle size for further processing. The RedUnit platform ranges from a single-stage hopper-fed grinder, to an all-in-one, combination 2-stage grinder and positive displacement pump.

Here are a few common RedUnit configurations, all provided as turnkey systems:

1) XRipper XRL with hopper (single-stage grinding, no pump)

2) XRipper XRL (Grinder) + CC Progressing Cavity Pump

3) XRipper XRL (Grinder*) + CC Progressing Cavity Pump + RotaCut (Macerator*) - *two stages of grinding

Other combinations of XRipper XRL and a VX Pump (Rotary Lobe) – shreds material then add liquid if needed, and pump the reduced particle size through discharge line

XRipper XRL: For package waste and materials requiring a fast, coarse grind

These units are quieter, typically occupy a smaller footprint, and require less service that solutions such as hammermills. A Vogelsang XRipper improves your waste reduction process by:

- Handling contaminants such sand and rocks with little wear.

- Using monolithic ripper rotors to grind through waste and packaging including cans, so there are no parts that will puncture, like the screen on a hammermill.

- Minimizing noise. Noise levels with a hammermill are very high. The XRipper’s smaller motor and engineered design minimizes that noise.

Multi-stage RedUnit Solutions: The All-in-One

Need to grind and pump high solids material in one process?

The Vogelsang RedUnit® can handle the toughest food waste without plugging. We’ve combined twin-shaft grinding, macerating and pumping into one powerful, efficient unit. Its powerful torque comes from our exclusive monolithic wider ripper rotor design. And it’s customized to your exact application and needs.

- Customizable, complete system including controls (plug and play)

- Turn solids into a pumpable medium

- Improved efficiency of drying equipment due to consistent solid particle size

- Available in stainless-steel construction

- No plugging due to higher torque grinding

- Increased lifetime and durability due to monolithic ripper rotors

- Low cost of service and repair

- Small footprint, retrofittable

- Complete control systems, stand alone or easily integrated with existing MCC systems

A Transfer Pump That’s Easier to Use and Service.

Transferring food waste can occur in many parts of a processing facility. We have one solution that works throughout your facility. The Vogelsang VX HiFlo® Rotary Lobe pump is the perfect solution for all your pumping needs. Unlike progressing cavity pumps that are used in many facilities, look at what the VX HiFlo pump will do to improve your waste transfer:

- Easy to service and maintain. It stays in place and inline and contains fewer parts that take a fraction of the time to service.

- Has a smaller footprint than other pumps.

- Can be stationary or mounted on a portable cart for use throughout the facility.

- Our pumps can run dry for up to 30 minutes.

- Virtually pulsation-free flow.

- Our cartridge mechanical seal with a seal bottle provides a leak-free chamber.

Learn more about the Vogelsang VX HiFlo pump here »

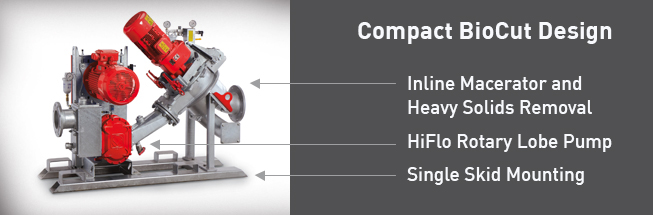

Combination Macerator & Pump

For processing facilities that are short on space, or are looking for the most efficient solution for solids reduction and pumping combined, Vogelsang has developed the BioCut®. It combines the outstanding maceration technology of our RotaCut with the high-performance operation of the VX HiFlo pump. The combined unit sits on one base and can be configured to be a single pumping station within an entire facility.

Feeding a digesters or meeting particle reduction requirements? This might be your solution.

It is also popular for individual applications such as:

- Liquid feeding

- Digester agitation

- Slurry transfer to the post-digester

- Material recirculation

- Upstream from the separation unit

- External heat exchanger

This versatility ensures cost-effective operation of the facility. Like all Vogelsang equipment, the BioCut is serviced inline. It also includes features such as auto-reverse, auto cut control, self-sharpening blades and reversible cutter screens available in various patterns.

CONTACT US

RedUnit, Solids Reduction

An adaptable system including XRipper, RotaCut, and either a CC or VX Series pump.