You need the right solids reduction technology for your application

RotaCut® is the reliable answer to efficiency

Vogelsang’s RotaCut® was developed for handling suspended solids, debris laden liquids and sludge processing. RotaCut's cutting action reduces organic waste and stringy materials down to a consistent particle size. This is something you’re not going to get that from a traditional twin-shaft grinder. Cutting systems on most twin-shaft grinders will grind through the inconsistent material, leaving it in various particle sizes and lengths. Stringy waste is more likely to to rag, clog and damage pumps and other equipment downstream. Rocks, metal and other heavy solids are going to stop the traditional grinder. But not RotaCut.

For consistent cutting, choose RotaCut, a wet macerator and a heavy material separator in one. The RotaCut reliably separates heavy objects like stone and metal, allowing them to drop into a separator bin, while macerating fibers, stringy and coarse material into uniform particles.

For biogas, this is especially helpful if you are supplementing your feedstock with corn and grass silage. For wastewater applications, this is perfect for sludge conditioning and removing heavy solids. RotaCut is also the ideal piece of equipment for other food waste applications where fine particle reduction is needed.

Standard RotaCut features include:

- AutoReverse

- Auto Cut Control (ACC)

- Self-sharpening blades

- Reversible cutter screens

- RotaCut is 100% rebuildable inline

RotaCut reduces your cost of service and repair. There are no cartridge-style parts that have to be sent out for reconditioning or factory refurbishment. All models features a quick release door allowing access to the cutting head. All RotaCut screens are reversible to allow for a fresh cutting surface without buying a new spare part.

Typical routine service such as changing blades or flipping the reversible cutting screen takes only a fraction of time required to service a typical twin-shaft grinder

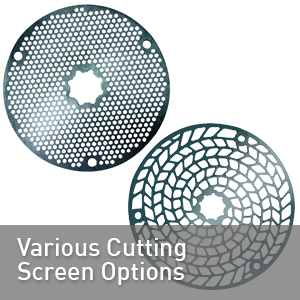

Adapt RotaCut to your operation using one of several pattern cuttings. Screens come in several patterns that will produce a designated size solid. The rotational speed of the cutting head also influences the solid size. The examples shown will produce different solid sizes and are easily interchangeable should operating conditions change. Screens are available in several material options for high wear applications. See RotaCut Models

Need a twin-shaft grinder that can run dry? Read more about XRipper

CONTACT US HERE, FOR DETAILS AND QUOTES

Video Demo: RotaCut In-line Macerator

Heavy debris removal and consistent cutting

Reliably macerates fibers in liquid media - prevents floating layers

CASE STUDY

Green Cow Facility Goshen, IN

RotaCut proves to be a better solution than twin-shaft grinder