Pumps for Fruit & Vegetable Waste: Installed cost is only part of the picture

When you look at new or replacement wastewater equipment for your food processing facility, it’s easy to pick the cheapest one. But when you only look at the initial cost of equipment you may be selling yourself short. Lifetime costs of a Vogelsang pump are much lower than other pump designs – especially if you are buying cheap. You may in fact be buying “disposable pumps.” And that’s just not cost effective. Here is how Vogelsang pumps stack up when making a pump purchase for operation:

Parts and Service

What is the cost of routine service and parts? Does the equipment come with a warranty? Be sure to find out if that warranty covers labor, parts and especially wear parts. Depending on your application, your supplier should be able to tell you how long it will be until you need routine service. Vogelsang pumps outperform other rotary lobe pump manufacturers and pump designs, with longer intervals between service.

Downtime During Repair

Will you have to send equipment back to the factory for service? Some pumps and solids reduction equipment requires factory service and rebuild. Will you need to keep a spare pump on hand “just in case?” Can your equipment be serviced and repaired online or in-house? How much income are your losing for every minute your equipment is out of service? Vogelsang pumps can be repaired inline without disconnecting pipes, and are easier and quicker to service than other pumps.

Service Agreements

Many companies sell a service agreement with their equipment purchases, requiring pumps to be sent back to the factory for service. Vogelsang pumps are serviced onsite and our replacement parts typically cost less than competitors.

Engineered Durability

How well does the equipment perform when faced with tough, abrasive or viscous debris? What are the typical service intervals? Can pumps run dry, and for how long in case of a clog downstream? Vogelsang pumps feature heavy-duty constructions and designed to work with abrasive and viscous media.

Vogelsang's "Pumps for Life" initiative is based on the idea that we engineer our pumps to stand up to tough applications, while being easy to service and maintain when needed.

Downstream Equipment Protection

What happens to your other equipment if your pump fails? What are the costs to replace those pieces and to clean up any spills or clogs? Avoid the domino effect by using a Vogelsang rotary lobe pump.

Efficiency

Are you using the most efficient equipment available? Centrifugal pumps are only able to operate with up to 3% solids. As the solids load goes up, the efficiency of a centrifugal pump drops quickly. So not only will you have to repair it more, it will cost you more when you are running it. You don’t use a sedan to haul a trailer, why use a centrifugal to pump solids? Vogelsang pumps are designed to handle high solid percentages with no loss of efficiency.

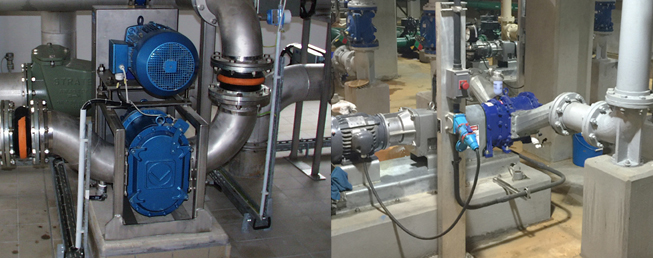

Footprint, Versatility

Does your pump take up valuable space on your floor? Can it fit into a tight space? Can you get a pump in the mounting configuration and motor option you need? Vogelsang rotary lobe pumps are compact and can easily be customized to your application needs. Need an inline electric motor? How about a piggy-back, belt drive? We can do that and more, all in the flow rates and percentage of solids you need.