DOES AN OUT-OF-THE-BOX SOLUTION WORK FOR EVERYONE?

The answer is a resounding no.

Depending on the type of septage you are receiving, the space you have to work with, and your budget, a one-size-fits-all septage station may not be in your best interest. Other companies may have fancy names for their products. Vogelsang has systems that are engineered to work -- and customized to work better -- to suit your needs.

Once we take a look at your requirements for septage receiving, we can build the perfect solution with our proven variety of tools and processes:

- Vogelsang’s heavy material trap designed to separate heavy solids.

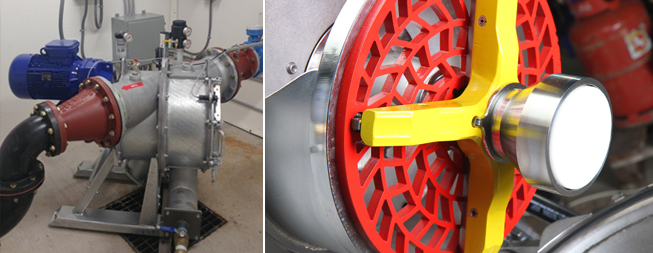

- Our RotaCut macerator provides consistent particle sizes as small as ¼” and is especially suited for FOG (Fats, Oils & Grease) applications.

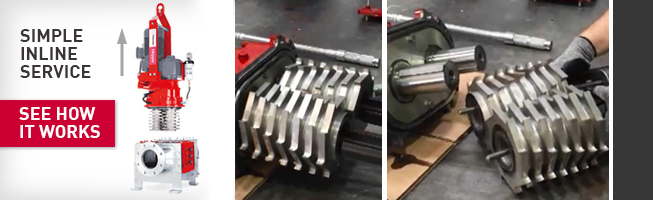

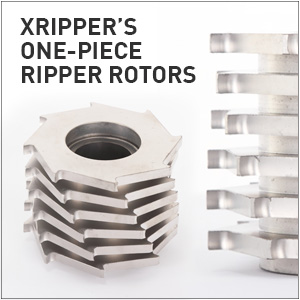

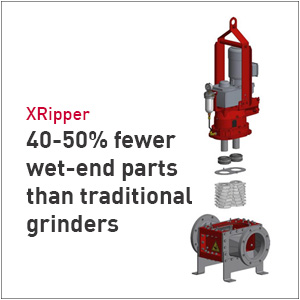

- The XRipper Twin-Shaft Grinder is the most robust in the industry with easier maintenance and less downtime, designed to not require a lower bearing.

- Vogelsang’s VX or IQ HiFlo Rotary Lobe Booster Pump which is low NPSHr with the ability to run dry and run both directions

- We can also add extras such as augers, control panels, gauges, plug valves, gate valves and VFDs

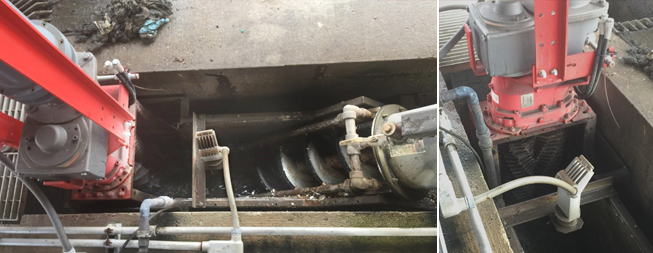

(Above) One Vogelsang septage receiving solution features a heavy material trap, XRipper twin-shaft grinder, and jib crane.

You can’t count on consistency

That’s why you can count on Vogelsang.

Today’s septage is not necessarily identical to yesterday’s. Varying viscosities and a mix of unwanted solids including rocks, rags, clothing, plastics, metal, and anything else that might be disposed of in a septage area can throw a curveball to some septage receiving operations.

A Vogelsang system takes inconsistency in stride. With a large heavy material trap, the heaviest solids are separated from the septage stream before they can cause trouble.

(Above) RotaCut macerator provides consistent particle sizes as small as ¼” and is especially suited for FOG applications

Our grinding and maceration equipment is engineered to avoid clogs and shutdowns. For example, the RotaCut has automatic reverse capability and uses Vogelsang’s Automatic Cut Control (ACC) to ensure constant pressure between the blades and cutting screen without having to re-adjust.

See more about RotaCut’s superior performance

Drop-in Replacement Grinders

When a system calls for a twin-shaft grinder, XRipper’s ripper rotors, made from one solid piece of steel, grind through the toughest material. These units are designed for high-torque grinding and easy-onsite maintenance.

Take a look at the XRipper’s robust design

More durable, easier to service

The ugly truth is that even though your receiving equipment stops, the septage keeps coming. How long can you be down while the haul trucks back up? Vogelsang equipment is engineered with more durable materials and smarter processes to keep working. You’ll get longer run times between service. And when you do need to do routine service – or repair something – your equipment will stay at home and inline to be serviced quickly and easily.

It’s easy to switch

If you’re disappointed with your current septage receiving station, or are experiencing another breakdown, you’re not stuck. Because we provide custom systems, we can work with you to replace whatever isn’t working. We’ll make it work, and make it fit – just for you.

Contact us today for information about a better septage receiving choice:

*Ask us how you can a new grinder for the cost of a repair

CONTACT US HERE

GET A NEW GRINDER FOR THE COST OF A REPAIR

Contact us before you repair or replace another twin-shaft grinder. We'll get you a new unit for the same cost of your repair.