XRipper® for Sewage Pumping/Lift Stations

How to Sell Vogelsang Twin-Shaft Grinders for Pump Stations or Lift Stations

Targets: Wastewater, Sewage Pumping Stations

Background:

Lift stations are an essential component of many municipal sewer systems. The main collection pipe transfers the wastewater to the lift stations by gravity. The pump/lift stations contain the grinders, pumps and valves needed to move sewage from a low to a high elevation. They are part of the sewer collection system prior to a wastewater treatment plant. A single municipality may have dozens of pumping stations under their jurisdiction.

Key personnel:

- Purchasing Manager

- Engineer

- Maintenance Manager

- Operations Manager

Goal:

- Replace the competitor's grinder - JWC®* models or similar design

- Provide a better solution than Grinder Pumps – our standpoint is that you can only do one or the other reliably and efficiently, grind or pump, but not both.

*JWC is a registered trademark of JWC Environmental, Inc., Costa Mesa, CA, USA. Vogelsang is not affiliated with JWC Environmental in any way.

XRipper Twin-Shaft Grinder for:

Pump Stations or Lift Stations

Clogged Grinder Pump:

XRipper Installation in Pump Station Well

Current Solution:

JWC Muffin Monster® Twin-Shaft Grinder*

Also: Grinder/Chopper Pumps and Screens

Advantages of the Current Solution:

- During normal operation, the unit provides the required grinding of the solids in the wastewater stream for pumping

What's wrong with the Current Solution:

Competitors' Twin-shaft Grinder:

- Maintenance is very high due to increased wear of the unit

- Individual blades and spacers will wear and separate over time

- During high volume, high solids occurrences, the grinder cannot keep up, causing it eventually to plug

- Due to the design of the these grinders, replacing the cutter stack and seals is very time-intensive and expensive

Grinder or Chopper Pumps:

- These pumps will struggle with larger solids and influxes of rags, wipes, and stringy material

- They do not match the particle size of twin-shaft grinders

- Service on grinder pumps is much more involved and time consuming when compared to twin-shaft grinders that can be easily pulled and serviced on-site

- In trying to both pump and grind in the same unit, these units tend to sacrifice efficiency

Vogelsang Solution: Vogelsang XRC Series Twin-Shaft Grinder

- “Drop-In Replacement" Program

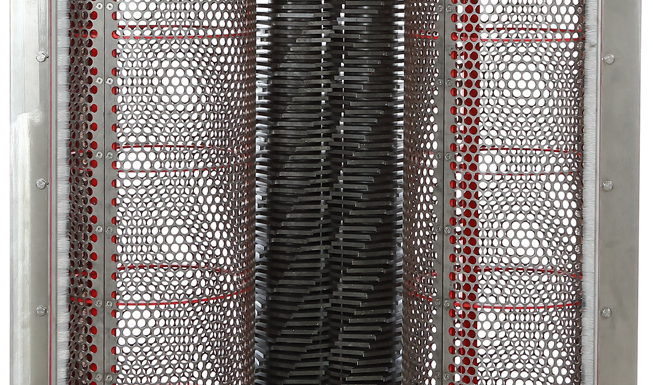

- Monolithic blades

Advantages Vogelsang:

- On-site maintenance and ripper rotor replacement

- Improved grinding performance, wider higher torque shredding and grinding

- Increased life-time and durability due to monolithic ripper rotors

- More robust design due to twin-shafted grinding design with monolithic ripper rotors and bigger

Why would someone change?

- They are having problems with their current grinder jamming

- Costly, time-intensive maintenance of cutter stacks and replacements

- Downtime due to blade stack loosening or waiting on replacement cartridges

- Vogelsang's drop-in replacement program provides a NEW grinder for the cost of repair

- We are able to match or exceed performance

- 2-year warranty, parts and labor -- including wear parts

XRipper Mounting

XRipper Grinder Overview

XRC Design

XRG MODELS FOR LARGE PUMP STATION CHANNELS

You view the full Engineering Guide for the XRG models here.

Get a new XRipper for the cost of a Repair

Supply the Competitor Make/Model and Drive Information

*JWC is a registered trademark of JWC Environmental, Inc., Costa Mesa, CA, USA. Vogelsang is not affiliated with JWC Environmental in any way.

VIRTUAL SHOWROOM

Wastewater products in a 360° digital experience

Step into our virtual wastewater world!

Sales and Marketing Resources

Click to View

CLICK HERE TO WATCH ON YOUTUBE

Grinder in Action

Handling 9 Tough Solids

See how the Twin Shaft Grinder is able to handle the most difficult solids.