Objective:

Choose a Grinder for Highflow Channels, Headworks & Pump Station Applications

Headworks and large open channels, including pump/lift stations, often require a grinder to handle diverse unscreened waste, including large inorganics.

Current Solution:

Competitor’s Grinder or Screening Systems

Advantages of the current Solution:

- Name recognition

- Adequate cutting under normal conditions

What’s wrong with the Current Solution:

- Screening systems are not effective in stopping all solids, often allowing wipes, bags and rags to pass through.

- Additionally, automatic screening systems are expensive

- While more economic bar screens are labor-intensive

- Maintenance is very high due to increased wear of the unit

- During high volume, high solids occurrences, the grinder cannot keep up, causing it eventually to plug

- Due to the design of these grinders, replacing the cutter stack and seals is very time-intensive and expensive

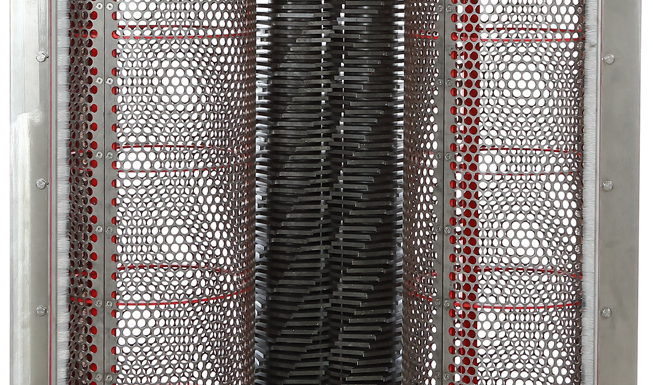

- Individual blades and spacers will wear and separate over time (shown below)

- Other twin-shaft grinders don't hold up to large debris and see performance drops too quickly

- Common channel grinders require center bearings that are susceptible to grit

Coil style "drums" (above) are prone to allowing wipes, rags plastic bags to enter the drum but not leaving. This causes clogging and a reduction in allowable flow. Over time the drums become packed which requires the unit to be pulled and left out to dried, at which time the debris has to be burned out of the drums.

What's the Vogelsang Solution?

Vogelsang's XRG, High-flow Grinder Series

Vogelsang has taken its XRipper twin-shaft grinder technology to a new level with the XRipper Giant (XRG). An extension of the company’s XRipper line, this design was developed for the harsh operating conditions and high-flow rates found in headworks and lift stations.

Our patent-pending design delivers consistent grinding on a larger scale than traditional grinders, in a unit that is rugged, but still maintenance friendly.

What are the Vogelsang Advantages

- Tackles larger solids with ease through its one-piece ripper rotors that feature high grip, curved tips

- More torque due to the larger diameter cutting elements and the monolithic ripper rotor

- No center bearings - monolithic ripper rotors don't require bearings in the middle of the cutter stack to maintain performance due to minimized shaft deflection

- Protects downstream equipment more effectively by reducing both large inorangics and troublesome waste such rags and wipes

Why would someone change?

- Increased wear of rotors and/or bearings has led to clogging that requires regular service and maintenance

- Performance is an issue. The unit can't handle the variety of larger solids alongside “flushable” wipes and rags that cause clogs

- Expensive repair and replacement programs - tired of feeling trapped in a cycle of high-cost repairs

- Repair time or waiting on replacements is leading to excessive downtime

- Lower cost of acquisition - XRipper units are typically priced 10-20% lower than the competition and can be priced to beat the cost of a repair/rebuild.

Key Comparative Feature:

Monolithic Cutting Elements

The patented technology used in the XRipper XRG is a Monolithic (One-Piece) Ripper Rotor. Precision machined from high quality hardened alloy; this cutter assembly is easy to remove in one piece without having to take out the complete grinder. This is a vast improvement over other twin-shaft grinders whose rotors are a column of stacked individual blades and spacers that can break down or wear unevenly. Maintenance time and costs for these traditional units is much higher than for the XRipper. Service technicians attending Vogelsang's recent Service School commented on how easy it is to service an XRipper, and that traditional cutter stacks in competitors' units are extremely time consuming.

One-Piece Construction, Fully Reversable

Cutting element is machined out of a single piece of steel; sturdy, solid construction with no blade loosening

- These are reversable, meaning the rotor can be flipped to counter the effects of uneven wear

Unique Teeth Design

Tested and optimized for the reduction of wipes, rags and other debris

Special Formulated Steel

Processed steel that is formulated to be ductile inside with a highly hardened outer surface

- Rotors are gas-nitrided resulting in high corrosion resistance

Sealed Ripper Rotor

Medium doesn’t come in contact with the shafts and shaft hub connection; no corrosion or wear

Key Comparative Feature:

Shaft Design and Shaft Deflection

Other manufactures use smaller diameter hex-shafts which can’t deliver torque like Vogelsang’s design. For XRipper XRG models, Vogelsang’s allows the one-piece rotors to act as the shafts, which are driven by larger diameter keyed shaft hubs. This design virtually eliminates shaft deflection; one of the primary causes of stress, wear, and breakdowns of the cutting system. Want a better performing unit that has longer service intervals? Choose the technology that has the least shaft deflection--Vogelsang XRipper.

*Illustrative Representation

A Closer Look at Shaft Deflection:

Key Comparative Feature:

Vogelsang Doesn't Require a Center Bearing

The heavy-duty, one-piece ripper rotors from Vogelsang don’t require a center bearing, as needed for support by other units--meaning one less common point of failure and less maintenance.

Channel grinders often require longer cutting stacks to compensate for high flows. In these cases, competitors units require a center bearing for stack heights of 24 inches and above. However, Vogelsang’s XRG series features one-piece ripper rotor, which are sturdy enough to not necessitate center bearings or extra support. Not only does this cut down on additional wear parts and maintenance work, it results in a more rigid cutting assembly.

DROP-IN REPLACEMENT OR SIZED TO REPLACE

The XRipper XRG can be a drop-in replacement for other twin shaft grinders or size matched to replace existing units. Below you'll see a successfully replacement installation in a wastewater treatment plant in Minnesota.

Screening Drum Options

The XRipper XRG High Flow Rotating Drum Design keeps debris moving in harsh conditions.

The XRipper Giant comes with either a single drum or double drum configuration, with maximum flows between 2,000gpm/2.8MGD and up-to 31,000gpm/45.0MGD. Minimum channel width required for the single drum unit is 21”/533mm and 54”/ 1372mm respectively for the double drum units.

Key Feature:

Only Vogelsang has Counter Blades for improved particle size reduction

In many grinders, the spacer on the top and bottom of the stack creates a gap in which material can pass through without being properly shredded. Vogelsang developed a special wear plate with counter teeth to reduce this gap and improve the particle size reduction.

Key Comparative Feature:

Warranty & Service

Common Grinder:

Warranty:

Offers a 1-1.5 year limited warranty. Manufacturer typically pushes an expense cartridge replacement program.

Service/Maintenance:

Due to the design of these grinders, working on the cutter stack and seals is very time intensive. Not only do the blades and spacers loosen and require tightening but trying to work on these cutters is a tedious process that requires the customer to alignment the dozens of blades and spacers that make up the cutter assembly. Often times customers have to accept a costly replacement program when service issues and downtime become unmanageable.

Vogelsang XRIpper:

Warranty:

Units come standard with a 2-year, parts & labor warranty, including wear parts. This ensure there are no service costs for the first two years of operation.

Service/Maintenance:

With 40-50% fewer wet-end parts than the competition, XRipper grinders are already much easier to manage from the maintenance perspective. And due to the cartridge mechanical seals and one-piece ripper rotors, a standard blade change is fast and less expensive. Standard maintenance procedures can be done onsite in as little to 1-2 hours.

Key Comparative:

Pricing

Lower cost of Acquisition: Vogelsang XRipper is typically priced 10-15% lower than the competition.

"Cost of a Repair" Pricing: XRipper is also available at "cost-of-a-repair" pricing, meaning if you are looking to replace a competitor's unit, we'll provide you with a new unit, including the motor, for the cost of your repair quote.

Lifetime Savings: Vogelsang has shown that our lower parts costs maintenance will save you thousands over the life of the unit. In most cases, a comparable repair on an XRipper is 25-30% lower than a competitor's units.

Vogelsang USA is the leading designer in pump and grinding technology, with products made and assembled in Ravenna, Ohio.

CLICK HERE TO WATCH ON YOUTUBE

Grinder in Action

Handling 9 Tough Solids

See how the Twin Shaft Grinder is able to handle the most difficult solids.

CASE STUDY

Porter Township WTP, Union Michigan

At this plant, a XRC 136-560QD was installed to accommodate a large number of solids. As a result, the X-Ripper saves the plant time and money by reducing maintenance and downtime.