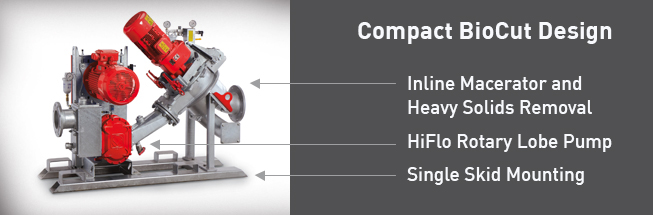

Add efficiency with BioCut® -- pump and cut in one unit

The BioCut consists of a self-priming rotary lobe pump combined with a special form of the tried-and-tested RotaCut. The RotaCut separates out the heavy material, protecting your system against foreign matter and preventing damage to the downstream components. Fibers and tissue are shredded by the cutter. This prevents clogging and gives the suspension the best possible composition for further processing. The degree of maceration and the desired throughput can be varied by adjusting the cutting screen geometry and the blade rotor speed.

In addition, the BioCut is designed as a central pump station and it can handle other pumping tasks within the system. These include emptying distributed storage pits and feeding other processes or systems.

Background:

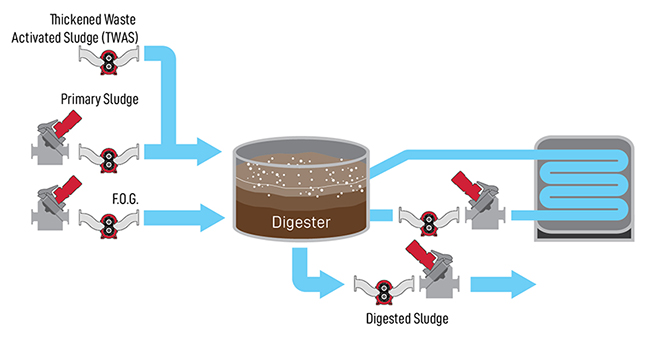

Municipal and Industrial Waste Treatment Plants use anaerobic digestion to treat biodegradable waste and sewage sludge. As part of an integrated waste management system, anaerobic digestion reduces the emission of landfill gas into the atmosphere. Digestion is a collection of processes by which microorganisms break down the biodegradable material in the absence of oxygen.

Anaerobic digestion is widely used as a source of renewable energy. The process produces a biogas, consisting of methane, carbon dioxide, and traces of other ‘contaminant’ gases. This biogas can be used directly as fuel, in combined heat and power gas engines, and can be upgraded to natural gas-quality biomethane. The nutrient-rich digestate that is also produced can be used as fertilizer.

TYPICAL APPLICATIONS

The BioCut is a compact, turnkey solution for pumping and handling solids in several digester applications such as:

- Digester Feeding

- Heat Exhanger Feeding

- Tank Cleaning or Circulation

Process Diagram:

Heat exchangers can often clog if stringy or fibrous solids are not properly cut and reduced in size

Current Solutions in this Application

- Progressing Cavity Pump

- Rotary Lobe Pump

- Double Disc Diaphragm pump

Advantages of the current Solution:

- Progressing cavity pumps can handle high solids loads with no pulsation.

- Double Disc Diaphragm pump has few moving parts, in theory should last a long time.

- Rotary Lobe Pumps have advantage of ease of maintenance and footprint.

What’s wrong with the Current Solution:

- Progressing cavity pumps have issues with high cost of spares, large amount of floor space they take up, and difficult maintenance that requires the pump to be pulled from the piping. Additionally, they are unable to run dry.

- Double Disc Diaphragm pumps can only handle solids up to 5%. They also require the use of pulsation dampeners to reduce pulsation to acceptable levels. Maintenance is difficult to do and requires stands to be able to perform the maintenance inline. The hinges that are used to support the lower housings are also prone to breakage.

- Other rotary lobe pumps use component seals. These are very difficult to replace in the field as the clearance between the stationary and rotary seat are very difficult to set properly. They have smaller shafts that are prone to deflection and fatigue, which reduces the life of the internal pump components. Wear liners are an extra wear item and require replacement when the lobes are replaced at a minimum. Other designs are not hydraulically balanced and can have some pulsation issues.

- Other systems do not have the flexibility of being able to offer a twin shaft grinder or macerator on the same skid as the pump.

Vogelsang Solution: BioCut

Vogelsang Advantages

- BioCut helps maintain a homogenous size of the solids in the digester to increase efficiency and reduce retention time.

- The Integrated pump and macerator of the BioCut ensures greater homogeneity of the sludge.

- BioCut helps keep the heat-exchanger clean, reducing the need for labor.

- The integrated rock trap also helps protect the system from any large foreign objects.

Video Demo: RotaCut In-line Macerator

Heavy debris removal and consistent cutting

Reliably macerates fibers in liquid media - prevents floating layers

Additional Resources