You need the right solids reduction and pumping technology for your biogas digester.

It’s what comes out that matters

Generating biogas from food and dairy waste is not a smooth process. To run efficiently, no matter what goes in, it all needs to come out the same. And it needs to flow properly to feed your digester. Vogelsang has been the innovator and industry leader in biogas technology since the beginning. We pride ourselves in sole source responsibility –that means any issue with your equipment takes just one call.

RotaCut® is the reliable answer to efficiency

Vogelsang’s RotaCut® was developed for biogas processing. To increase efficiency of the digestion process, the optimized solid particle size going to your digester needs to be consistent -- around 4-5mm (3/16”). With manure digester feedstock you’re not going to get that from a traditional twin-shaft grinder. Rotors will grind through the inconsistent material, leaving it in various particle sizes and lengths. Straw and other stringy waste is going to rag, clog and damage pumps and other equipment downstream. Rocks, metal and other heavy solids are going to stop the traditional grinder.

RotaCut is a wet macerator and a heavy material separator in one. The units reliably separates heavy objects like stone and metal, allowing them to drop into a separator bin, while macerating fibers, stringy and coarse material into uniform particles. This is especially helpful if you are supplementing your feedstock with corn and grass silage.

RotaCut is used on the suction side of submersible pumps that feed manure into the anaerobic digester tank. It can also be used at the point of recirculation to further refine sludge.

Standard RotaCut features include:

- AutoReverse

- Auto Cut Control (ACC)

- Self-sharpening blades

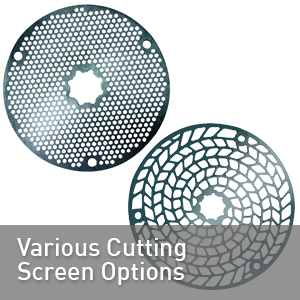

- Reversible cutter screens

- RotaCut is 100% rebuildable inline

RotaCut reduces your cost of service and repair. There are no cartridge-style parts that have to be sent out for reconditioning or factory refurbishment. The RCX model features a quick release door allowing access to the cutting head. All RotaCut screens are reversible to allow for a fresh cutting surface without buying a new spare part.

Typical routine service such as changing blades or flipping the reversible cutting screen takes only a fraction of time required to service a typical twin-shaft grinder

Adapt RotaCut to your operation using one of several pattern cuttings. Screens come in several patterns that will produce a designated size solid. The rotational speed of the cutting head also influences the solid size. The examples shown will produce different solid sizes and are easily interchangeable should operating conditions change. Screens are available in several material options for high wear applications. See RotaCut Models

The VX Pump keeps things flowing smoothly

Used for manure, tank transfer and recirculation applications within a biogas operation, the Vogelsang HiFlo VX Series rotary lobe pump is the premier positive displacement pump on the market. The unique lobe design outperforms progressing cavity, centrifugal and other rotary lobe pumps. It is built to pump thick and abrasive sludge with no pulsation. A unique convoluted lobe design provides a large cavity well-suited to biogas feed. The design also allows the pump to achieve required pressure at a lower rpm. This means less damage to the lobes and minimal wear on the rest of the pump.

Take a look at the benefits of the Vogelsang VX Series Pump:

- Less expensive to maintain than a progressing cavity pump.

- Pulsation free which results in less wear and tear and surrounding equipment and piping.

- A seal chamber with seal bottle keeps pumpage from leaking out of the pump even in the event of a seal leak.

- Can run dry for up to 30 minutes without issue.

- Pumps mediums over a wide viscosity range, so there is no need for a separate pump for thick and thin mediums.

Vogelsang rotary lobe pumps can pull up to a 25’ lift, so underground storage tanks are no problem to pump from.

Read more about the superior design of the Vogelsang VX Pump

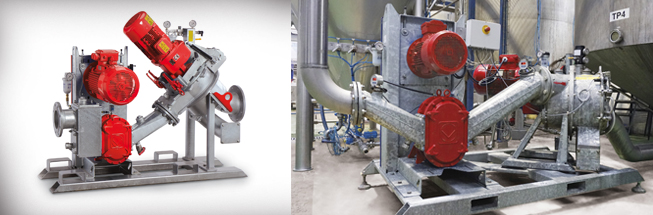

BioCut® combines economical pumping with perfect maceration

Vogelsang is the creator of BioCut -- the most innovative technology developed specifically for biogas applications. Combining pumping and solids reduction, the BioCut® is the all-in-one answer to processing manure to biogas. Its design combines the Vogelsang VX Series Rotary Lobe Pump with a RotaCut wet macerator. BioCut optimizes liquid introduction with an economical pump and combines it with perfect maceration of fibrous material. It fits into most existing biogas plant configurations and can be serviced in-line.

Biogas facilities love the BioCut because it:

- Provides pulsation free flow

- Has mechanical seals with a seal bottle to provide a leak-free seal chamber.

- Is easy to maintain in place

- Provides a consistent size particle on the output providing more homogenization of the solids which leads to better, more efficient digestion

- Does not need to be removed from the system to maintain it

- Expedites blade replacements in as little as 30 minutes of downtime

- Has a integral rock trap that allows heavy solids to fall out of the waste stream rather than accumulate in the digester

- Has a compact footprint and only needs one equipment pad for pump and macerator in one

- Can be moved to the digester for further solids reduction and recirculation

See BioCut Used in a Digester Cleaning Application:

XRipper, Twin-Shaft Grinder

If your biogas operation brings in by-product substrate materials from other industries such as food waste, rendering and fats, the Vogelsang XRipper will integrate these feedstocks into your digester flow.

These high-energy materials require the proper size reduction and conditioning before being fed into the digester. XRipper is perfect for most food wastes from apples, potatoes, beets, corn and various other fruits and vegetables. Since XRipper can run dry, it can work in both wet and dry substrate applications. Read more about XRipper

BIOGAS CASE STUDY: XRipper Keeps Debris from Clogging Pump

Here are the advantages of adding an XRipper to your biogas operation:

- On-site maintenance and ripper rotor replacement

- No lower bearing

- More robust design due to twin-shafted grinding design with monolithic ripper rotors and bigger diameter rotors

- No plugging due to higher torque grinding

- Increased life-time and durability due to monolithic ripper rotors

- Low cost of service and repair

- Less wet end grinder parts

- Oil-lubricated mechanical cartridge seals

CONTACT US HERE, FOR DETAILS AND QUOTES

Digester Cleaning

Handling heavy viscous sludge with debris

BioCut is our VX Rotary Lobe Pump and RotaCut Inline Grinder configured on a common skid for easy installation

Video Demo: RotaCut In-line Macerator

Heavy debris removal and consistent cutting

Reliably macerates fibers in liquid media - prevents floating layers

CASE STUDY

Green Cow Facility Goshen, IN

RotaCut proves to be a better solution than twin-shaft grinder

Biogas Efficiency Calculator

Simply input the individual values of your system

You can calculate the savings for your system based on the EU-AGRO BIOGAS research project