Vogelsang's XRG, High-flow Grinder Series

Vogelsang has taken its XRipper twin-shaft grinder technology to a new level with the XRipper Giant (XRG). An extension of the company’s XRipper line, this design was developed for the harsh operating conditions and high-flow rates found in headworks and lift stations. Our patent-pending design delivers consistent grinding on a larger scale than traditional grinders, in a unit that is rugged, but still maintenance friendly.

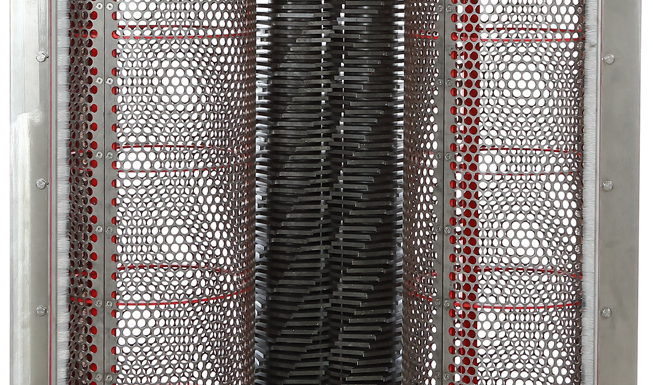

Patented Monolithic Cutting Elements & Easy Maintenance

The patented technology used in the XRipper XRG is a Monolithic (One-Piece) Ripper Rotor. Precision machined from high quality hardened alloy, this cutter assembly is easy to remove in one piece without having to take out the complete grinder. This is a vast improvement over other twin-shaft grinders whose rotors are a column of stacked individual blades and spacers that can break down or wear unevenly. Maintenance time and costs for these traditional units is much higher than for the XRipper. Service technicians attending Vogelsang's recent Service School commented on how easy it is to service an XRipper, and that traditional cutter stacks in competitors' units are extremely time-consuming.

Read more about the XRIPPER HERE

The XRipper XRG High Flow Rotating Drum Design keeps debris moving in harsh conditions.

The XRipper XRG can be a drop-in replacement for other twin shaft grinders. Below you'll see a successfully replacement installation in a wastewater treatment plant in Minnesota.

Screening Drum Options

The XRipper Giant comes with either a single drum or double drum configuration, with maximum flows between 2,000gpm/2.8MGD and 31,000gpm/45.0MGD. Minimum channel width required for the single drum unit is 21”/533mm and 42”/ 1372mm for the double drum unit.

Vogelsang USA is the leading designer in pump and grinding technology, with products made and assembled in Ravenna, Ohio.

CONTACT US

CLICK HERE TO WATCH ON YOUTUBE

Grinder in Action

Handling 9 Tough Solids

See how the Twin Shaft Grinder is able to handle the most difficult solids.

CASE STUDY

Porter Township WTP, Union Michigan

At this plant, a XRC 136-560QD was installed to accommodate a large number of solids. As a result, the X-Ripper saves the plant time and money by reducing maintenance and downtime.