Wipes-Related Issues Stealing Headlines Again: COVID-19 Spurs Clogging Issues for Sewer Districts

“Cities across the country are seeing an increase in wipes showing up in sanitary sewer pipe systems and causing problems during COVID-19,” said Raleigh Water Assistant Director TJ Lynch. Source

Wastewater pump clogs and other issues due to "flushable" wipes are making headlines again. Across the country millions of people are staying at home due to COVID-19. And the evidence suggests that, on-mass, the public is using wet-wipes, disinfectant wipes, paper towels, and are otherwise putting items down their toilet that don't below in the waste stream. As a wastewater systems employee, you may already be dealing with these issues.

We're Here to Help, and in Full Production

For those of you trying to keep your wastewater system running, know that Vogelsang’s XRipper grinders can provide a solution to wipes and other debris. We carry a full line of grinders for in-channel and in-pipe applications. Note, Vogelsang is still in full production and lead times are still in a typical range.

Drop-in replacements -- get a new twin-shaft grinder for the cost of a repair

Whether you need a new grinder added to your system, or you're looking to replace a failing or under performing twin-shaft grinder, we make choosing a Vogelsang XRipper easy. We'll get you a new service-friendly, drop-in replacement unit quickly, and at cost savings other other typical units.

Not only is Vogelsang's XRipper twin-shaft grinder designed to fit in the exact same space as your old grinder, we are currently offering new units at the cost of your repair.

How this works:

- Send us the details on your current twin-shaft grinder -- a repair/replacement quote is even better

- We'll return a price-match offer on a brand new XRipper twin-shaft grinder that matches the specs of your current unit, including the grinder and motor. Additionally, you get:

- A 2-year, 100% manufacturers parts and labor warranty, including wear and tear parts, such as cutters and mechanical seals

- The options to re-use your existing controls, so not only does the new unit drop into place, it can plug into your existing set-up and be running in no time

- Thousands in savings over the life of your XRipper through its reliability and lower repair costs

> Contact us for details using the form on this page

Choose from a full line of XRipper Models:

Twin-shaft grinders for: headworks channels, inlets, pump stations, and pipeline applications

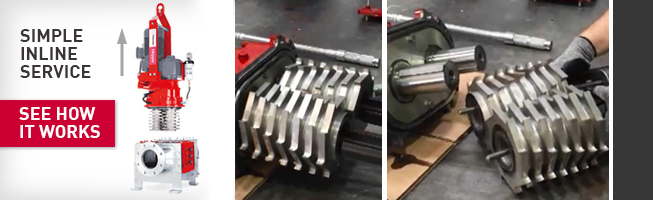

Easy Onsite Service

XRipper grinders don't require expensive replacement programs or factory rebuilds. With designs that feature 50% fewer wet-ends parts than the competition, XRipper is simple to maintain and service onsite.

- In-line maintenance -- easily pull the unit from the housing or bracket system

- Our one-piece ripper rotors allow for the cutting elements to be changed far more easily than other grinders that feature individual blades and spacers

- Durable Cartridge Mechanical Seals that are easy to change

- No lower bearing on in-pipe units

Unique Monothlic Ripper Rotors

XRipper is a robust, high-torque grinder. Both its performance and longevity come as a result of our one-piece, monolithic ripper rotors. Unlike units that feature individual blades and spacers, our ripper rotors will never loosen or require tightening because of wear.

Need more details?

Contact us using the form on this page