ONE PUMP DOES IT ALL

THE MULTI-TASKING PUMP FOR MUST, LEES, PUMP-OVER, PRESSED JUICE AND BARREL RACKING

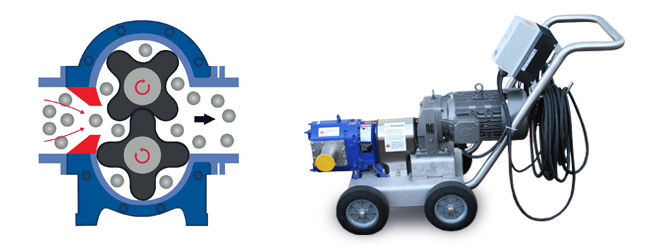

Imagine being able to use one piece of equipment to pump grapes and juice throughout your winery. The Vogelsang HiFlo® Rotary Lobe Pump is capable of just that. The HiFlo® pump design is compact and available in various models to meet your size and flow requirements. Available on either portable carts or stationary units, we can configure a custom turn-key system that fits your requirements and works hard all over your winery.

One pump design for your maintenance team to learn and maintain, with a low up-front cost, and the ability to grow with your business.

Portable Wine Carts

The multi-use pump can also be mounted on a four-wheel 304 stainless steel cart that can have VFD with remote speed control, or a control panel or other controls mounted for quick connection. Hoses can take the same pump from must to pump-over and beyond.

Stationary Pumps

The HiFlo® lobe pump is compact and configured to fit in small hard-to-reach spaces and can be mounted in any direction to fit into your current pipe, tank, and crush pad configuration. We will work with you to combine cart pumps, stationary units, screw sumps, and controls into a powerful and simple set-up for your system.

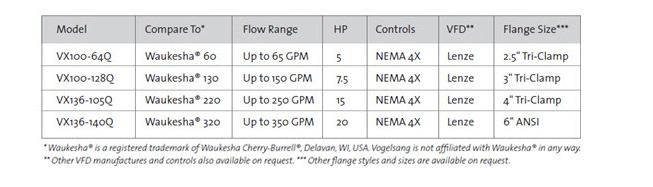

Specifications: Vogelsang VX-Series Pumps - Request Pricing/Quote

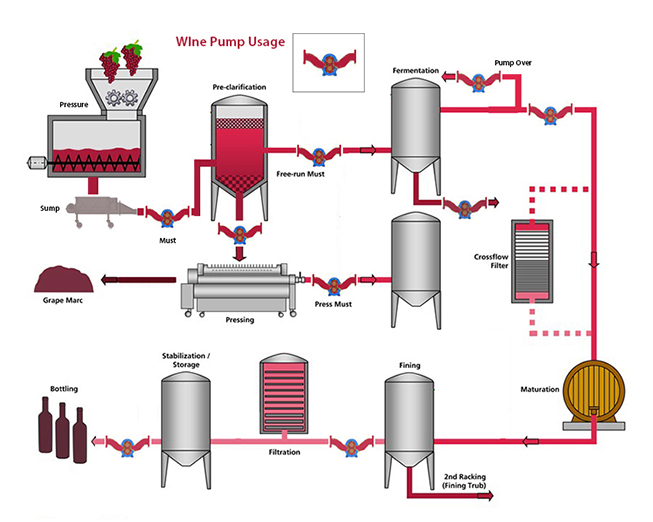

Wine Pump Applications

The Pump for Must & Lees

The best pump to move must or lees is the one that handles them gently and delivers them intact without clogging, locking or losing flow/pressure. Unlike metal rotary lobe pumps, the HiFlo® pump has elastomeric coated rotors that gently move grapes and even whole clusters. Because of the elastomeric coating, the rotors are not affected by staples and other foreign debris so they don’t lock up to cause a stoppage right in the middle of crush. Centrifugal pumps used by many wineries need high RPM (1800 RPPM) to achieve adequate pressure, doing tremendous damage to your grapes. Our unique convoluted rotor design provides a large pumping cavity so our pumps do not need to revolve as fast (300-400 RPM) to achieve the appropriate flow/pressure (up to 4.400gpm) to move grapes and juice with minimal damage and low shear. Progressing cavity pumps tend to smash grapes and seeds, releasing oil and tannins into the juice that affects the taste of your wine, and can also severely damage grape skins.

Vogelsang pumps are also the perfect pump for lees. The HiFlo® design does not lose prime like a centrifugal pump is known to do as the solids become thicker as the tank is emptied. You can pump highly viscous lees solids without needing manual intervention.

Pump-Over

The Vogelsang HiFlo® Rotary Lobe Pump is ideal for pump-over as it runs with minimal shear – the lowest in the industry. When used for pump-over, the Vogelsang HiFlo® Rotary Lobe Pump is pulsation free. The higher flow with lower RPM design means you can run pump-over and extract the most flavor from the must. In contrast, other pump designs such as progressing cavity, centrifugal and peristaltic pumps use excessive force to achieve adequate flow/pressure required. The more times juice is circulated, the more air is introduced -- it’s like putting your precious fruit and juice in a blender.

Our pumps are self-priming, up to 25’. They can also run dry for as long as 30 minutes preventing stoppage and additional maintenance.

Pressed Juice & Barrel Racking

The intermeshed convoluted rotors of the HiFlo® pump move in unison to create a constant flow rate, drawing juice into an expanding cavity, then pumping it out on the discharge end with less pulsation and high efficiency. This low pulsation makes it ideal for transfer of pressed juice and for barrel racking.

Our pumps are warranted against damage from run dry with absolutely no liquid for up to 30 minutes – much longer than you probably will ever need. This keeps your tank/tubs drier than other pumps. Progressing cavity pumps and flexible impeller pumps require liquid to be present at all times so you don't run the pump dry. You can start and stop our pumps instantly between batches without re-priming or damaging wine.

NO STOPPAGE PUMPS

Staples don’t stop us.

Staples, wood fragments, clips, stones – bring ‘em on.

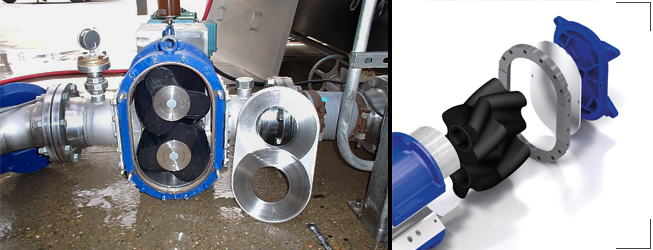

The last thing you need during crush season is a breakdown or stoppage. The Vogelsang HiFlo® pump isn’t affected by debris such as staples, trellis clips, wood fragments and stones that cause damage and lock-up other pumps. Our exclusive InjectionSystem housing and the elastomeric coating on our rotors eliminates hard objects from getting caught in the pump. The pump won’t lock up and sustain the damage that metal lobe pumps are known for. There are no delicate hoses or stators to damage. Your grapes and juice will stay undamaged and off the floor.

InjectionSystem housing is a design option that's perfect for wine pumping applications. Watch the Video:

In-line maintenance and repair

If your pump has to be sent back to the factory for repair or maintenance, you can be unproductive for days or weeks. Vogelsang HiFlo® pumps are 100% maintained and serviced in-line at your winery. We feature quick and easy access to internal pump parts, even without removal of the piping. Changing wet-end parts doesn’t require disconnecting your pump. Routine service is a breeze thanks to quick access front cover, adjustable housing segments, replaceable wear plates, and hard-faced cartridge mechanical seals that can go several seasons without replacement, unlike packing, lip seals and O-ring type seals.

Easy access to change wet-end parts without disconnecting the pump.

Does your pump Self-Prime?

Although most wineries need a suction lift of 5’ or less, our pumps are designed to be self-priming up to 25’. This allows you to start and stop pumping, then continue the process instantly between batches without re-priming, and to avoid heating up causing damage due to dry run.

Can Your Pumps Run Dry?

Do you have a Progressive cavity pumps or flexible impeller pumps that require liquid to be present at all times? Running pumps dry can cause headaches during crush, but also once the season is over. Vogelsang HiFlo® pumps can run dry for up to 30 minutes. Much longer than you should ever need.

See how a smarter rotary lobe pump can optimize your production.

GENTLE ON GRAPES

Grapes love our HiFlo® Rotary Lobe Pump

Rotary lobe pumps provide the most delicate must transfer and pump-over for winemaking. We’ve taken the rotary lobe design one step further to design an even smarter pump with better materials and an efficient design that handles grapes, seeds, skins and juice gently. Our unique HiFlo® rotor design provides minimum shear when compared to traditional metal rotary lobe, centrifugal, and progressive cavity pumps.

Smarter design channels solids more efficiently with less impact on must and pump.

The smarter, gentler must pump

Unlike metal rotary lobe pumps, the HiFlo® pump has elastomeric rotors that gently move grapes and clusters. The HiFlo® elastomeric rotors, are not affected by staples and other foreign debris. The convoluted rotor design provides a larger cavity so you can achieve solids up to 2.4” without crushing berries, seeds and skins, without locking up on staples and other debris. The HiFlo® design provides your desired flow (up to 4.400gpm) with a slower RPM due to multiple rotor tips. The Patented InjectionSystem housing optimizes the flow path to further reduce lobe wear, and does little to no damage to your precious product.

Lowest shear in the industry.

Pump-over with minimal shear

When used for pump-over, the Vogelsang HiFlo® Rotary Lobe Pump is pulsation free for the lowest shear in the industry. The higher flow/low RPM design means you can run your pump-over longer to extract the most flavor from the must with little to no sheer. In contrast, other pump designs such as centrifugal and pumps use excessive sheer to achieve the adequate flow rate required. These pumps typically run at 1800 + RPM, whereas the HiFlo® lobe design only requires a maximum of ½ of that speed. The more times juice is circulated, the more air is introduced -- it’s like putting your precious fruit and juice in a blender.

Designed for must handling and pump-overs.

See how a smarter rotary lobe pump can optimize your production.

WINE PUMP BUYER'S GUIDE

Pump Comparison

Gain deeper knowledge on the application and what's best for your wine making needs.

Video Testimonial

Vogelsang's Pumps Help Italian Winemakers

Hear it from the customer: how Vogelsang is unique in the rotary lobe pump category

HIFLO® PUMPING DEMO

VIDEO: SEE HOW IT WORKS

See how a smarter rotary lobe pump can optimize your production

Gentle Pumping

MINIMAL SHEAR

Vogelsang Pumps don't crush seeds and won't aerate your juice like other pumps

No stoppages

VOGELSANG RELIABLITY

Designed to eliminate stoppages, dry run, and self-prime up to 25’