ALL ROTARY LOBE PUMPS ARE NOT THE SAME

Ours is better. Better engineering. Better performance.

Our engineers took the basic rotary lobe design and set out to make a better pump. That was 80 years ago. And throughout the years, we have continued to be responsible for major innovations and advances in positive displacement rotary lobe pump design.

The resulting Vogelsang VX and IQ Pumps have improved performance, longer maintenance intervals, and are easier and quicker to service. This comes from several design innovations unique to the industry that make our pumps ideal for viscous liquids, heavy solids & abrasives. Take a look at what makes Vogelsang Rotary Lobe pumps different – and better.

Watch this overview video and read more below:

HiFlo® Lobe Design

The secret to Vogelsang VX and IQ Rotary Lobe Pumps being virtually 100% pulsation free is in the lobes. Our four- and six-lobe designs eliminate pulsation and are more efficient than other pumps, therefore lasting longer. We have tried designing with two-tip and three-tip lobes, but we found pump efficiency gets steadily worse as the lobes wear.

Our lobes are one solid piece of metal or metal with an elastomer wrap, depending on the application. Other rotary lobe pumps boast replaceable tips as a benefit. But separate tips are difficult to install and remove, and may come loose during operation. It is common for grit to work its way into the track and mechanical fixtures. Tip breakage can cause other pump damage like couplings, shafts, timing gears, and lobe cores.

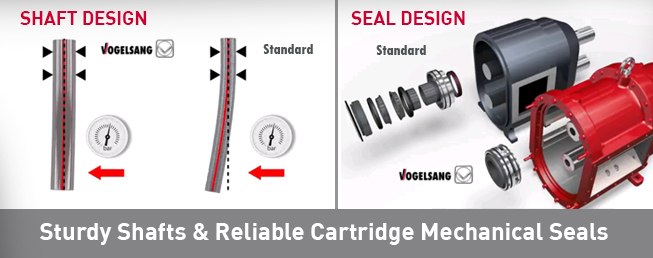

A Better Seal

Component pump seals are a 3-part system with a stationary seat, a rotating seat, and a setting device that is either a collar or a threaded device. These seals have to be manually set, must be kept clean, and if the seal fails, It causes a mess, pumpage can enter the bearing frame, can leak on the floor, etc.

Our Block Ring Cartridge Mechanical Seal is the pump industry’s most advanced innovation in sealing technology and is only available from Vogelsang. The hard Block Ring surface is wear resistant, especially against fibrous matter. Abrasion affects only the Block-Ring not the seal itself. This design allows for excellent heat transfer due to the large block ring acting as a heat sink and transferring this to the pumpage and shaft. Due to the greatly improved heat dissipation, our seal is also insensitive to dry running.

Large Diameter Shaft - No Step-Down Design

Vogelsang pumps feature the largest diameter shafts in the rotary lobe pump category. In addition to small diameter shafts, other lobe pumps feature a step-down shaft design which further increases the amount of deflection--resulting in decreased efficiency and increased wear on wet-end parts.

Vogelsang's larger shaft diameter greatly reduces shaft deflection which dramatically improves pump life cycle and performance.

Adjustable Housing Segments

Over time, due to natural wear, the gap between the lobes and your housing will increase resulting in a decrease in pump performance. Vogelsang pumps feature housing segments that can be adjusted to close the gap and compensate for this wear. This simple, inline maintenance procedure allows you to extend the life of your lobes while also maintaining near-factory performance. This feature is in contrast to the competition’s one-piece casting, that will require you replace lobes more often.

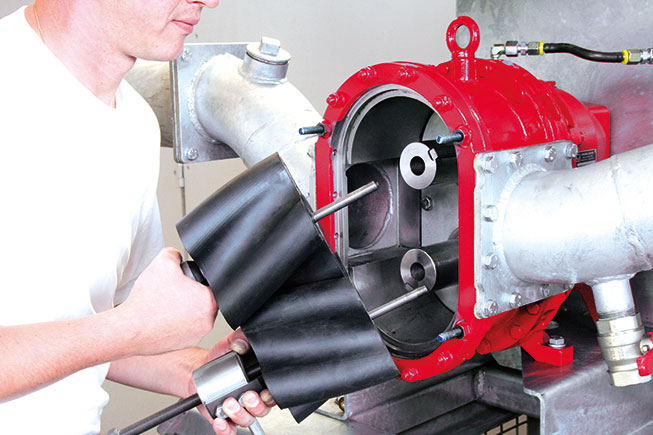

Easy In-line Service & Maintenance

Vogelsang Rotary lobe pumps feature an QuickService design. Not only can you access the entire wet-end of the pump in minutes without disconnecting the pump, our seals are easier to install than most other rotary pumps, and adjustable housing segments mean you can get more life out of a set of lobes. On a standard VX Q-Series pump, basic maintenance can be done on the spot in 1-2 hours.

CONTACT US