Process FOG with Vogelsang's Advanced Pumps and Grinders

Application: RotaCut or XRipper with VX or IQ Pump

Background: FOG (Fat, Oil, and Grease) is becoming an increasingly major disposal problem. Regulations limit the amount of FOG that can be discharged and it therefore has to be disposed. Wastewater utilities want to keep FOG out of collection systems. FOG boosts the gas production in the digesters, but it needs to be handled properly as it effects the treatment process and adds additional challenges throughout the plant.

Most of the time, FOG is transported to the processing plant by tankers. It may be pumped into an EQ or balancing tank and then fed to the plant continuously. Larger plants may be able to direct feed it to their process. Depending upon the source, unrelated solids may be present in the FOG. FOG from restaurants often contains silverware or utensils. Dairy FOG may have stones or hair in the waste. Municipal interceptors may have plastic bags or utensils present, etc.

FOG sources include:

- Residential waste

- Commercial waste

- Restaurant waste

- Mobile home park waste

- Porta-Potty waste

- Industrial waste

- Food processing facility waste

How Does FOG Differ From Septage?

FOG typically has much higher solids content than septage and the pH (while it tends to be lower due to fatty acids) has a wider range as compared to septage. Due to the higher solid content, it is much more difficult to pump than septage (which is frequently handled with centrifugal pumps).

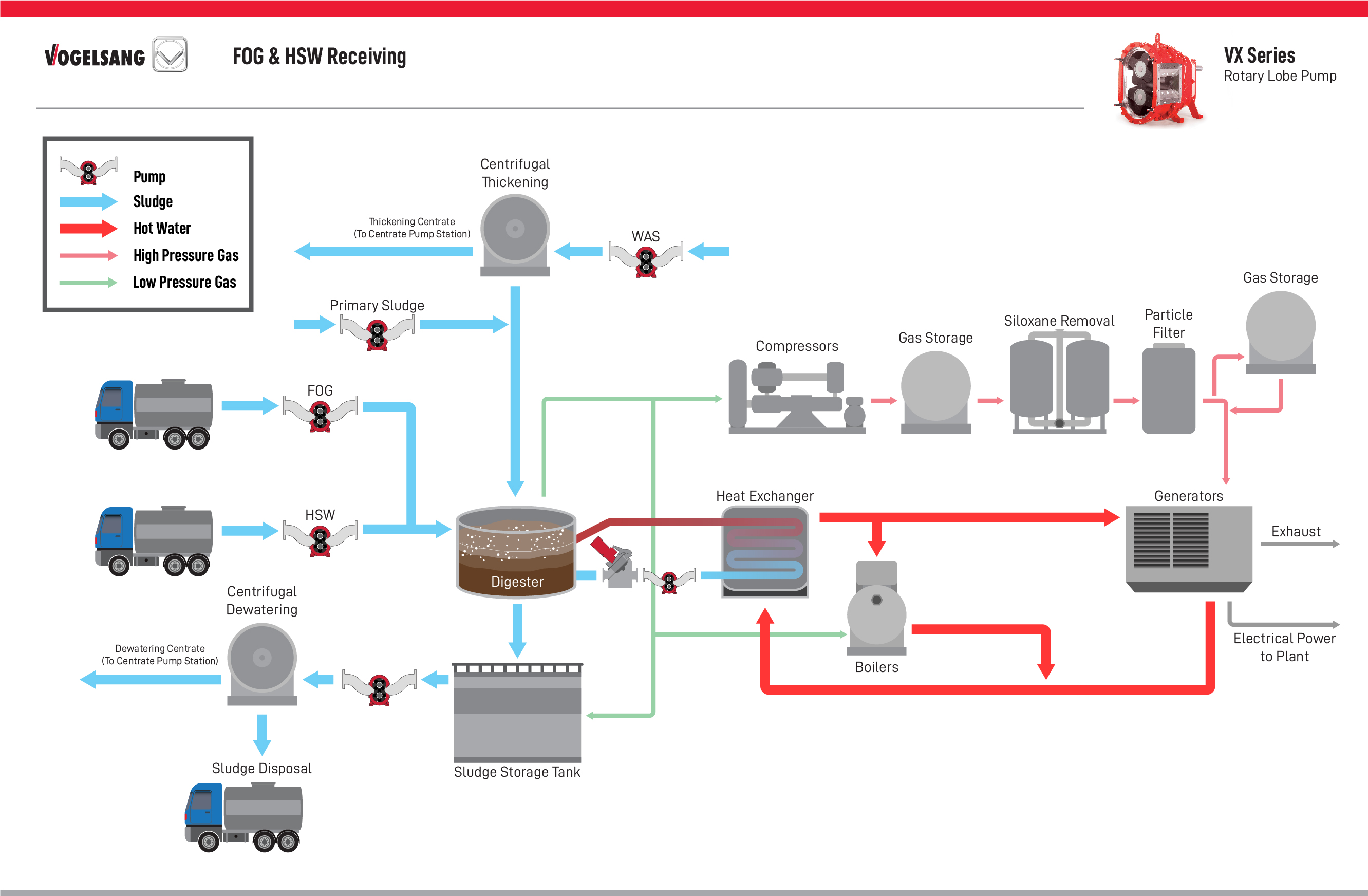

Process Diagram:

Current Solution

- Progressing Cavity Pump

- Competitive Rotary Lobe Pump

- Gear Pump

- Out-of-the-Box Receiving Station

- Centrifugal Pump

Advantages of the Current Solution:

- Progressing cavity pumps

- Can handle heavy solids load

- Can handle various viscosities

- Gear Pump

- Cost

- Can handle viscosity

- Out-of-the-Box Receiving Station

- One stop shop

- No need to coordinate multiple pieces of equipment, its all in one

- Centrifugal Pump

- Cost

What’s wrong with the Current Solution:

- Other manufacturers may be grinding experts or pump experts, but are not both

- Pumps need to be removed from the piping for servicing

- Centrifugal pumps

- Are only good up to 3% solids, at the end of a run, the last batch of solids can be much higher than 3%.

- FOG applications have varying viscosity loads. Centrifugals have issues with viscous applications.

- Progressing cavity pumps

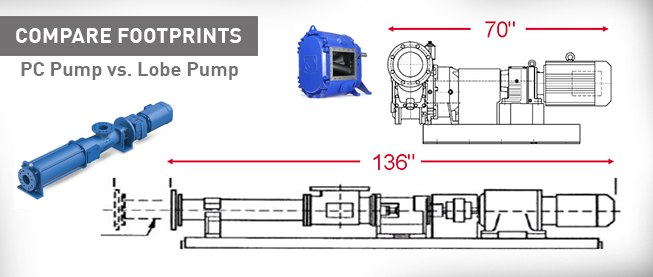

- Large footprint: 40-60% larger than Rotary Lobe Pumps

- Cost of maintenance: Parts are typically ~40% more costly than Rotary Lobe Pumps

- Not easy to maintain/repair: Requires that the pump be pulled from the line, often takes days rather than hours as with Rotary Lobe Pumps

- Cannot run dry: Rotary Lobe Pumps can run dry up to 30min

- Gear Pump

- Cannot handle solids

- Competitive Rotary Lobe Pumps

- A smaller diameter, stepped shaft design creates more shaft deflection leading to premature wear of lobes and housing (FOG tends to have high discharge pressure)

- Do not have a block ring cartridge mechanical seal

- Do not have injection housings, have higher wear characteristics. Injection housings eliminate solids recirculation on the inlet side of the pump. This reduces wear because the solids only interact with the lobes once.

Vogelsang Solution:

- All-in-one customizable systems with either RotaCut or XRipper with VX or IQ Pump.

- Complete systems cover a small foot-print.

- FOG is pumped through a rock trap (optional) then on to either an XRipper or RotaCut.

- We can also add extras such as control panels, gauges, plug valves, gate valves and VFDs

Vogelsang Typical Offering

- Cast Iron Housing with TC coating

- Injection A Housing

- NBR lobes

- Tungsten Carbide vs. Silicon Carbide Block Ring Cartridge Seal

- Hardox wear plates with TC coating

Vogelsang Advantages:

- Vogelsang’s heavy material trap designed to separate heavy solids.

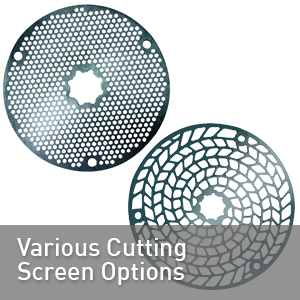

- Our RotaCut macerator provides consistent particle sizes as small as ¼” and is especially suited for FOG (Fats, Oils & Grease) applications.

- The XRipper Twin-Shaft Grinder has proven to outlast competitors units in various head-to-head trials while being easier to maintain; less downtime. Designed to not require a lower bearing in XRP/in-pipe models.

- Vogelsang’s VX or IQ HiFlo Rotary Lobe Booster Pump which is low NPSHr with the ability to run dry and run both directions

- Vogelsang pumps can handle flows with a wide range of solid loads.

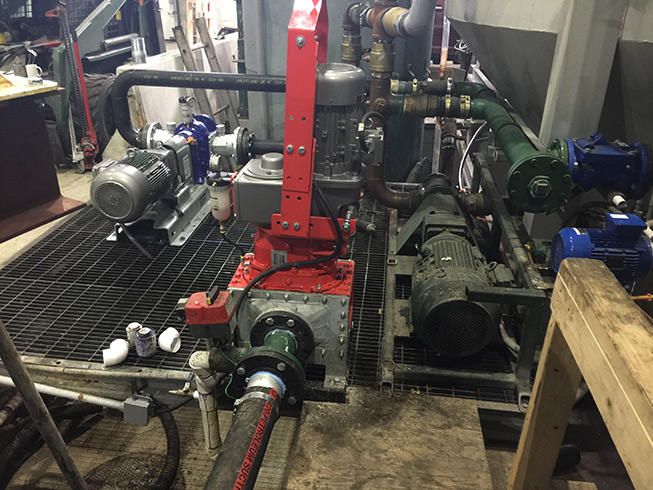

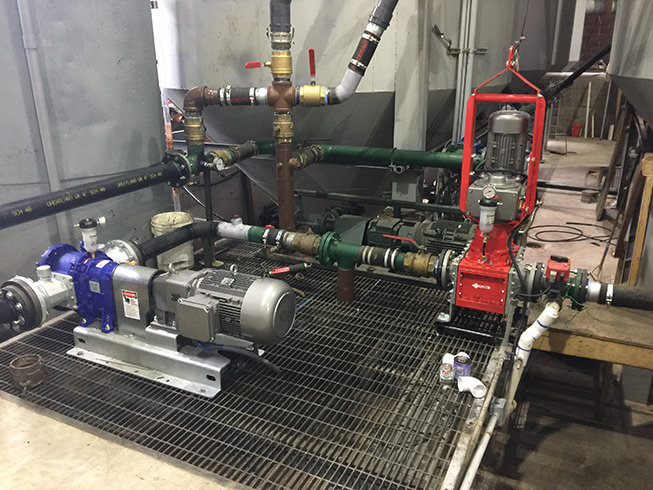

Feature Installation: Northeast Environmental, XRipper & VX-Series

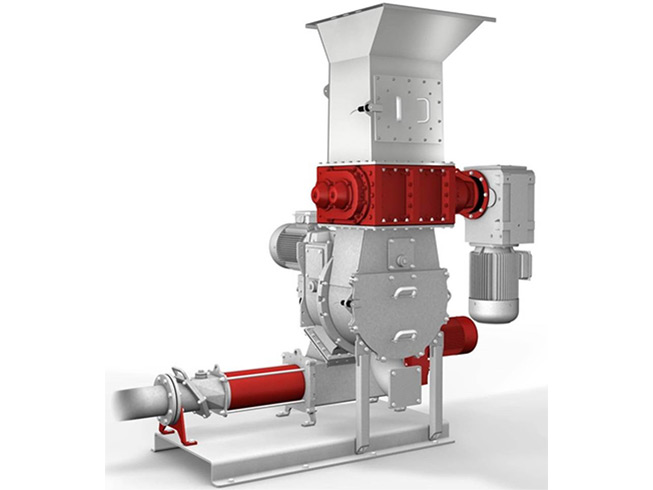

Other Food Waste Handling Options - RedUnit, Solids Reduction

As cities move towards keeping food waste out of landfills, and state and local restrictions are placed on disposal of pre and post-consumer waste, more opportunities emerge for recycling and biogas programs.

Vogelsang has extensive experience in handling organic waste outside of FOG. Our RedUnit systems (solids “Red”duction units) provide a method for turning dry matter and mixed organic waste into a semi-liquefied mixture that is suitable for processing by digesters and other waste handling systems.

Common applications:

- Food waste from expired products from grocery stores. A large percentage never makes it to the consumer and, per regulations, has to be processed accordingly. This pre-consumer food waste is often used for fertilizer or biogas production, where solids particle size reduction is one of the first steps.

- Similar processes are in-place to deal with post-consumer food waste, such as restaurant scraps or cafeteria waste.

Vogelsang, VX-Series Rotary Lobe Pump Overview

Here’s a look at the operating principal and key features of Vogelsang’s VX-Series Rotary Lobe Pumps.

Video Demo: RotaCut In-line Macerator

Heavy debris removal and consistent cutting

Reliably macerates fibers in liquid media - prevents floating layers