XRipper Prepares for Biogas Triple-Play

Problem Summary:

Scenic View Dairy’s 2,500 cows produce more than 100,000 pounds of manure daily. This manure, along with various organic additives is pumped into a digester – a concrete storage tank-- to produce biogas for energy by means of anaerobic digestion. However, large debris in the manure such as straw and hooves were clogging the pump and the lines going to the digester.

Solution Summary:

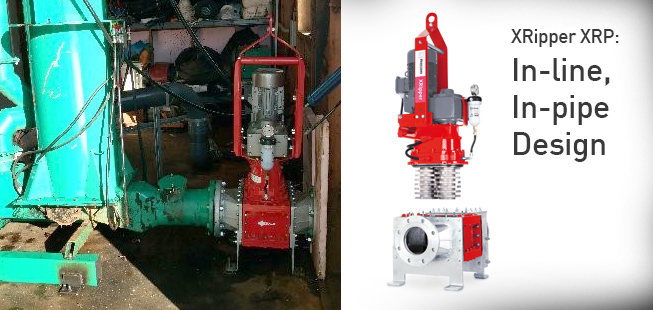

Install the Vogelsang XRipper XRP136-200Q/8inch Twin-Shaft Grinder on the suction side of a GEA-Houle piston pump to reduce solids before they are pumped into the digester tank.

The Customer:

Scenic View is the first dairy farm in central Michigan using dairy cow manure and various organic additives to generate biogas using anaerobic digestion. The dairy has received recognition from the community and national organizations for its natural energy production and recycling programs.

Currently, electricity that is generated from the waste is first utilized on-site to power the dairy, and then the excess electricity is placed on the local power grid. In addition to the production of energy, the byproducts of anaerobic digestion include organic liquid used to provide nutrients for crops. The solids, known as “biofibers” are used for animal bedding.

The Problem:

The dairy was having issues with large debris, cow hooves, and straw clogging their pump and lines going to the digester. Operations had to be shut down for weekly clean-outs.

The Solution:

To reduce the solids in the manure before they reached the pump, Vogelsang suggested the XRipper136-2000/8inch Twin-Shaft Grinder be installed on the suction side of an existing piston pump that pumps the manure mixture into an anaerobic digester tank.

Vogelsang visited the dairy and did an inline demonstration of the grinder, showing the difference between the Vogelsang rotary lobe pump and other styles and competitors’ pumps. Scenic View Dairy installed the XRipper and was immediately able to eliminate the weekly pump and line clean outs.

Advantages of the Vogelsang Solution:

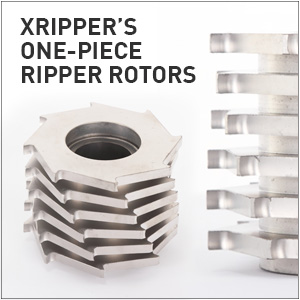

Along with the more affordable cost of the Vogelsang unit over other company’s products, the XRipper design features monolithic cutters and no bottom bearings. This provides a more robust system to grind solids found in the manure stream before they reach the pump. The reliability of the XRipper keeping things flowing was the most important factor to the dairy - 150 GPM with solids content of 6% by volume.

Benefit for the user:

After installing the XRipper, the dairy eliminated weekly clean outs of the pump and lines and quickly saw a return on investment in labor and pump parts savings

XRIPPER, TWIN-SHAFT GRINDER

If your biogas operation brings in by-product substrate materials from other industries such as food waste, rendering and fats, the Vogelsang XRipper will integrate these feedstocks into your digester flow.

These high-energy materials require the proper size reduction and conditioning before being fed into the digester. XRipper is perfect for most food wastes from apples, potatoes, beets, corn and various other fruits and vegetables. Since XRipper can run dry, it can work in both wet and dry substrate applications.

Here are the advantages of adding an XRipper to your biogas operation:

- On-site maintenance and ripper rotor replacement

- No lower bearing

- More robust design due to twin-shafted grinding design with monolithic ripper rotors and bigger diameter rotors

- No plugging due to higher torque grinding

- Increased life-time and durability due to monolithic ripper rotors

- Low cost of service and repair

- Less wet end grinder parts

- Oil-lubricated mechanical cartridge seals

CONTACT US HERE, FOR DETAILS AND QUOTES

Video Demo: XRipper Grinder

Serious Torque, Easy On-site Service

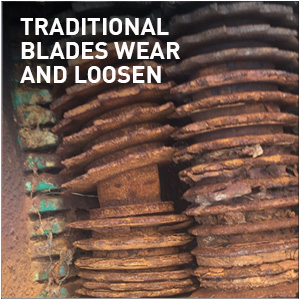

Take down debris with this high-torque design that doesn't require factory rebuilds or expensive replacements like other common grinders

GET A QUOTE

XRipper is a drop-replacement for most common grinders

Need more information on Xripper? Talk to an expert or request a quote on this linked page