VOGELSANG WASTEWATER SOLUTIONS

Vogelsang’s complete line of rotary lobe pumps, twin shaft grinders, and maceration equipment can provide quick solutions for your sewage and sludge applications.

Rotary Lobe Pumps with Superior Features

Vogelsang has been manufacturing since 1929 and have learned a thing or two about rotary lobe pump design. Unlike other pumps on the market, the Vogelsang HiFlo® pump provide a multitude of standard design features and benefits that other products don’t include.

Items such as these listed below give our pumps the lifespan you expect in your toughest applications:

- Largest diameter shafts, no step-down design

- Cartridge mechanical seals

- HiFlo®, pulsation free lobes

- Adjustable housing segments

- Reversible wear plates

It doesn’t stop there. Through fluid dynamics we have reinvented the rotary lobe pump housing design resulting in the IQ pump.

Request a Rotary Lobe Pump Quote

Don’t Grind When You Really Need to Cut

Twin shaft grinders provide a one-step approach to grinding solids, but sometimes it’s just better to cut. RotaCut® was specifically designed to not only size reduce your solids, but even cut hair, rags, and plastics that can get through your fine screens and into the plant. With its exclusive Automatic Cut Control (ACC®), the unit is designed to provide a sheer cut to anything in your sludge, reducing fibrous material down to a small particle size that will eliminate plugs in heat exchanges, valves, flow meters, etc.

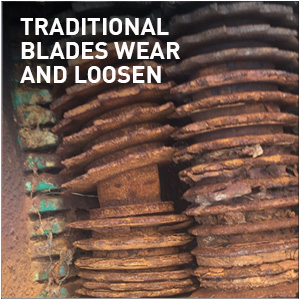

Not All Twin Shaft Grinders are Equal

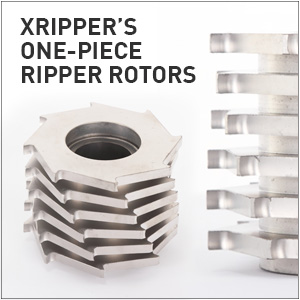

We didn’t invent the twin shaft grinder, but we did make some much-needed improvements in a design that hasn’t changed in decades! Vogelsang XRipper™ was specifically designed to solve the common issues found in the grinders of today. Say goodbye loose cutter stacks that are common with systems that use individual blades and spacers.

Get a better twin-shaft grinder with XRipper:

- Monolithic Riper Rotors - high-torque, no loose stacks of blades and spacers

- 40-50% fewer parts than competition - less to fail, easier to service

- Easy onsite maintenance - no expensive replacement programs

- Drop-in replacement - same flange-to-flange and centerline dimensions as competitors; you can even use your old control system

- Get a new unit for the cost of a repair

NEED MORE INFO:

CONTACT US

Applications Diagram

Find out where you can use Vogelsang equipment

Sludges, Scum, Dewatering Feed, DAFT, Septage, Solids handling and more

XRIPPER DEMO VIDEO

XRipper Shreds 7 Tough Solids

Before & After: Grinding of wipes, clothing, wood, and even a boot